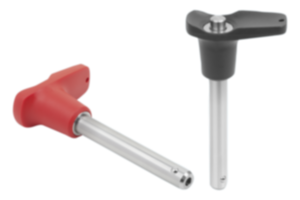

{"product":{"productId":"agid.1504","price":22.37,"name":"Ball lock pins with aluminum L-grip"},"currency":"USD"}

Material

Pin 1.4542 stainless steel.

Grip die-cast aluminum EN-AC 46000.

Push button aluminum EN-AW 2024 T4.

Balls 1.4125 stainless steel.

Spring stainless steel wire.

Version

All stainless steel parts passivated.

Pin hardened to min. 40 HRC.

Grip black anodized.

Push button blue anodized.

Balls hardened to 58 +4 HRC.

Pin hardened to min. 40 HRC.

Grip black anodized.

Push button blue anodized.

Balls hardened to 58 +4 HRC.

Afficher plus

Afficher moins

Description

Material

Pin 1.4542 stainless steel.

Grip die-cast aluminum EN-AC 46000.

Push button aluminum EN-AW 2024 T4.

Balls 1.4125 stainless steel.

Spring stainless steel wire.

Version

All stainless steel parts passivated.

Pin hardened to min. 40 HRC.

Grip black anodized.

Push button blue anodized.

Balls hardened to 58 +4 HRC.

Pin hardened to min. 40 HRC.

Grip black anodized.

Push button blue anodized.

Balls hardened to 58 +4 HRC.

Note

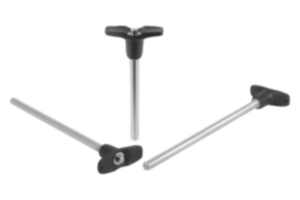

Ball lock pins are used for easy fastening or joining of components or workpieces.

The two balls are disengaged by pressing the push button and the pin can be slipped into holes in the workpieces. Release the button to lock the balls and secure the connection. If required, the ball lock pins can be fitted with a retaining cable.

The hardened, high-tensile stainless steel pin permits extreme loads with low wear.

Shear force double shear (F) = S · τ aB max.

The values given for the shear force are the theoretical breaking load.

These are non-binding reference values without consideration of safety factors and exclude any liability. The values given are for information purposes only and do not constitute a legally binding assurance of properties.

The load values have been calculated in accordance with DIN 50141. Each user must determine individually whether the ball lock pin is suitable for the respective application.

Different materials in which the ball lock pins are used, weather conditions and wear can influence the determined values.

The two balls are disengaged by pressing the push button and the pin can be slipped into holes in the workpieces. Release the button to lock the balls and secure the connection. If required, the ball lock pins can be fitted with a retaining cable.

The hardened, high-tensile stainless steel pin permits extreme loads with low wear.

Shear force double shear (F) = S · τ aB max.

The values given for the shear force are the theoretical breaking load.

These are non-binding reference values without consideration of safety factors and exclude any liability. The values given are for information purposes only and do not constitute a legally binding assurance of properties.

The load values have been calculated in accordance with DIN 50141. Each user must determine individually whether the ball lock pin is suitable for the respective application.

Different materials in which the ball lock pins are used, weather conditions and wear can influence the determined values.

Accessory

Safety spiral cable K0367.10200

Retaining cable with loop K0367. .....

Key ring K0367.15/19/23

bushinging for ball lock pins K0724....

Retaining cable with loop K0367. .....

Key ring K0367.15/19/23

bushinging for ball lock pins K0724....

Remarque importante concernant le téléchargement des modèles CAO

Pour pouvoir télécharger nos modèles CAO, vous devez d’abord connecter. Si vous n’avez pas encore créé de compte, inscrivez-vous en cliquant sur « Mon compte » (à droite de l’écran) et suivez les instructions.