{"product":{"productId":"agid.26599","price":413.83,"name":"Swing clamp pneumatic screw-on"},"currency":"USD"}

Material

Body aluminum.

Piston steel.

Piston steel.

Version

Body black anodized.

Piston hard chrome-plated

Piston hard chrome-plated

Show more

Show less

Description

Material

Body aluminum.

Piston steel.

Piston steel.

Version

Body black anodized.

Piston hard chrome-plated

Piston hard chrome-plated

Note

Screw-in pneumatic swing clamps find use where low clamping forces suffice and where the clamping point has to be cleared to enable placing or removing the workpiece.

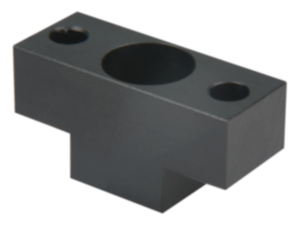

The design enables space saving installation. The screw-in bolt can be used to adjust the height of the swing clamp. The clamp is suitable for a sunken mounting in a fixture.

Due to the double-acting function of the clamp, pressure is used to move the piston downwards and upwards.

The total travel of the swing clamp consists of the swing travel and the clamping travel. At the start of the clamping process, the clamping arm performs a 90° swing movement. When this movement is completed, the linear down clamping travel is carried out. The workpiece must only be clamped using the clamping travel.

The swing clamp must not be constrained in its swinging action. F1 = at 6 bar max. permitted operating pressure.

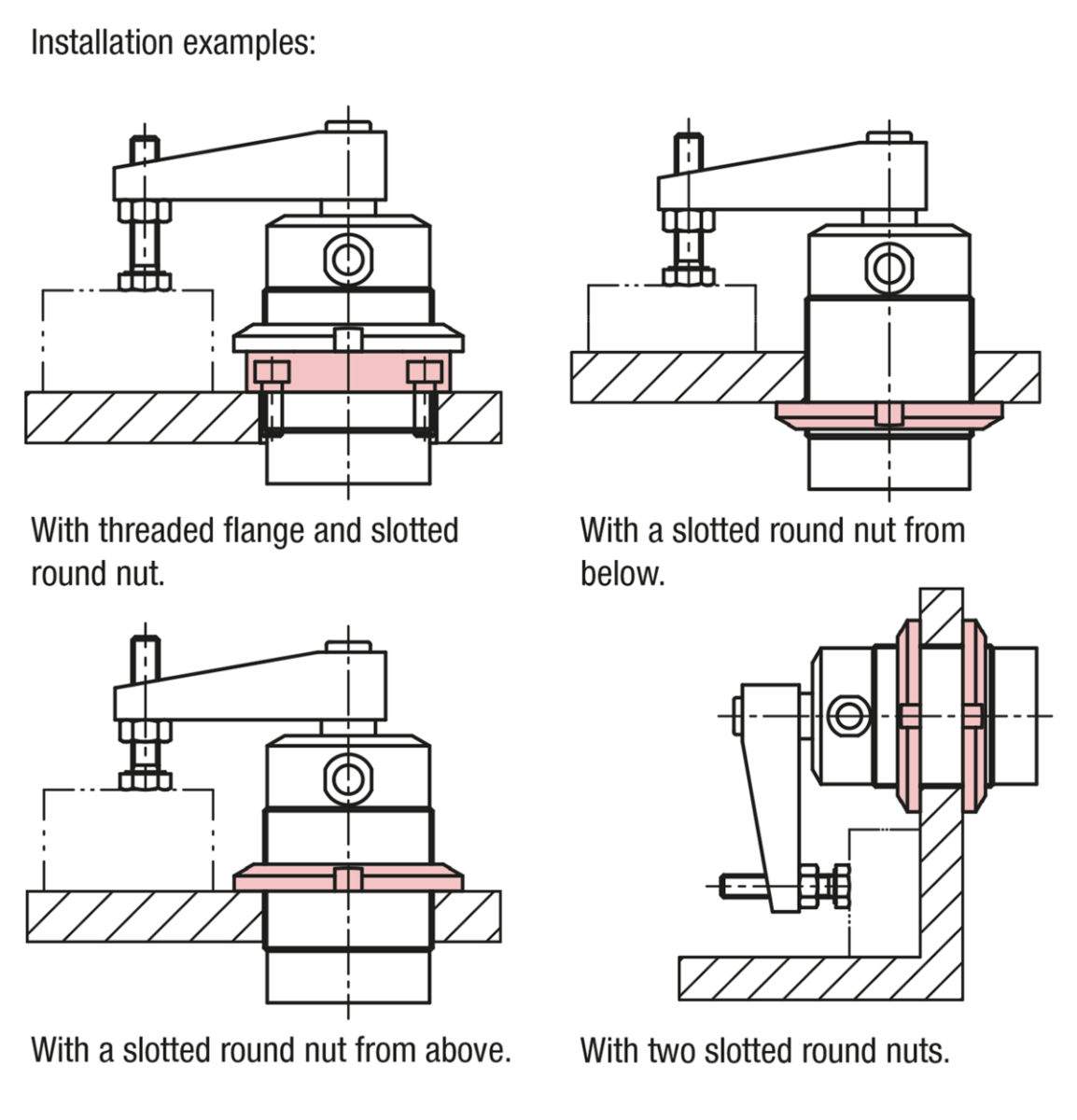

The screw-in swing clamp can be fastened using a DIN 70852 slotted round nut or a threaded flange (K1820).

The swing clamp must only be operated using lubricated air.

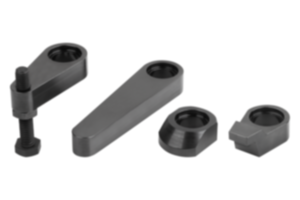

Including screw and lock washer for fastening the clamping arms which are available as accessories.

Clamping arm, slotted round nut and threaded flange are not supplied.

The design enables space saving installation. The screw-in bolt can be used to adjust the height of the swing clamp. The clamp is suitable for a sunken mounting in a fixture.

Due to the double-acting function of the clamp, pressure is used to move the piston downwards and upwards.

The total travel of the swing clamp consists of the swing travel and the clamping travel. At the start of the clamping process, the clamping arm performs a 90° swing movement. When this movement is completed, the linear down clamping travel is carried out. The workpiece must only be clamped using the clamping travel.

The swing clamp must not be constrained in its swinging action. F1 = at 6 bar max. permitted operating pressure.

The screw-in swing clamp can be fastened using a DIN 70852 slotted round nut or a threaded flange (K1820).

The swing clamp must only be operated using lubricated air.

Including screw and lock washer for fastening the clamping arms which are available as accessories.

Clamping arm, slotted round nut and threaded flange are not supplied.

Drawing reference

1) Clamping

2) Releasing

3) Swing travel

4) Clamping travel

5) Relaxed

6) Tensioned

7) Left swinging

8) Right swinging

2) Releasing

3) Swing travel

4) Clamping travel

5) Relaxed

6) Tensioned

7) Left swinging

8) Right swinging

Accessory

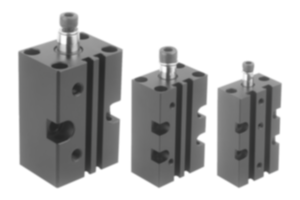

K1816 Clamping arm for swing clamp.

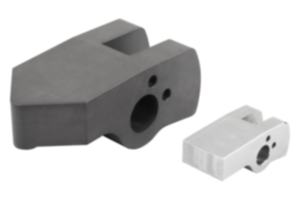

K2059 Slotted round nut, steel DIN 70852.

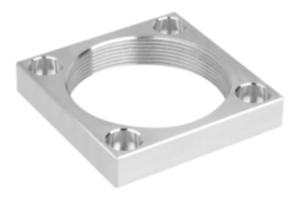

K1820 Threaded flange.

K2059 Slotted round nut, steel DIN 70852.

K1820 Threaded flange.

Important note on downloading CAD models

You must log in before you can download our CAD models. If you have not yet created an account, please register under "My account" (right-hand side of the screen) and follow the instructions.