{"product":{"productId":"agid.27162","price":76.29,"name":"Screw-in hydraulic cylinders single-acting with spring return"},"currency":"USD"}

Material

Housing and piston steel.

Seal NBR

Seal NBR

Version

Housing black oxidized.

Piston hardened.

Piston hardened.

Show more

Show less

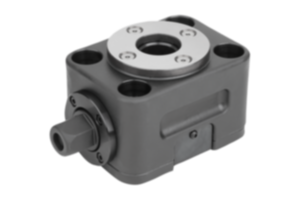

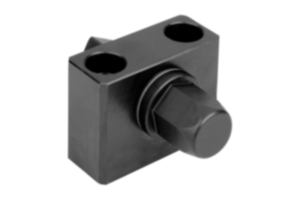

Screw-in hydraulic cylinders, single-acting with spring return, style A

from

$108.99

as low as | plus sales tax

plus shipping and handling

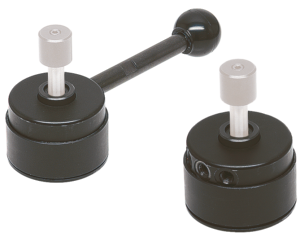

Screw-in hydraulic cylinders, single-acting with spring return, style B

from

$121.10

as low as | plus sales tax

plus shipping and handling

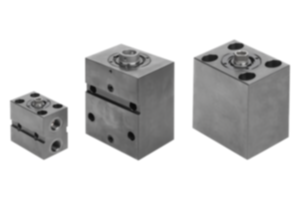

Screw-in hydraulic cylinders, single-acting with spring return, style C

from

$191.74

as low as | plus sales tax

plus shipping and handling

Description

Product description

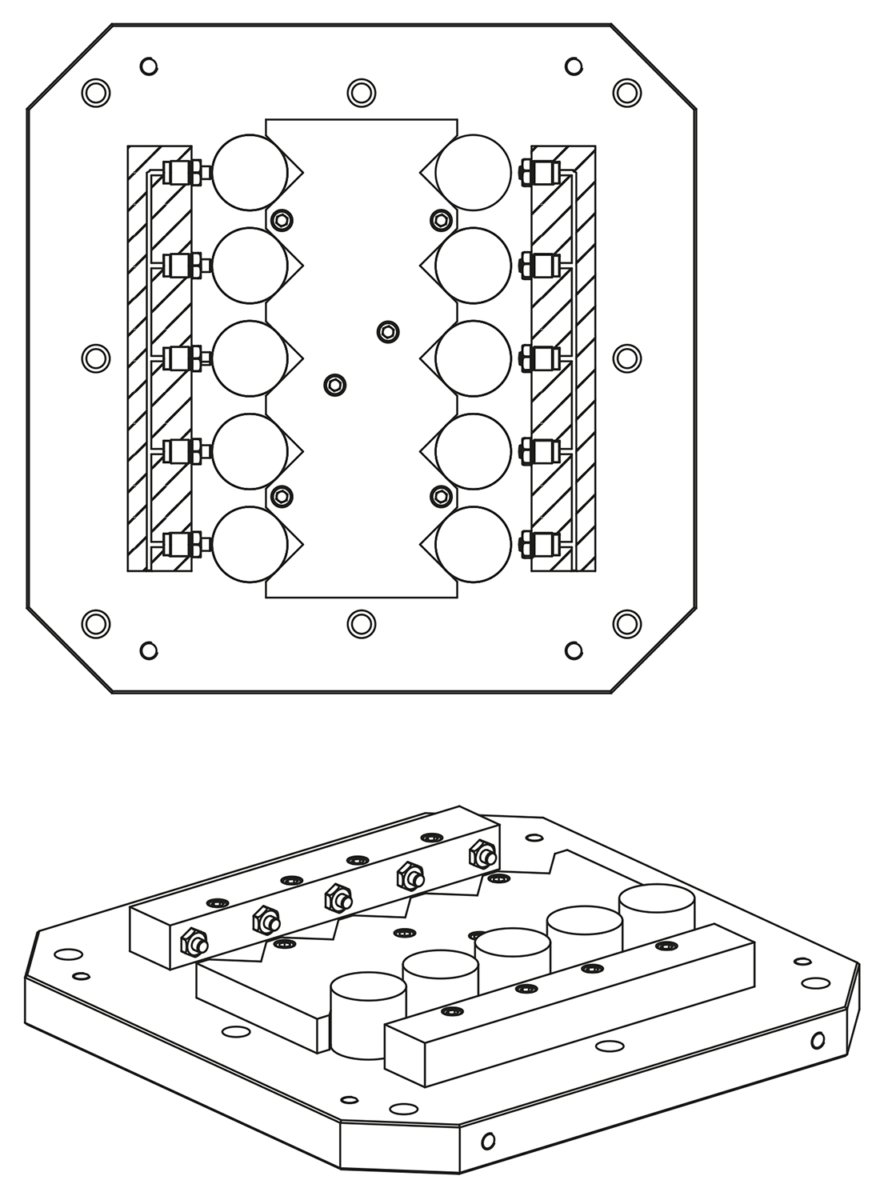

The single-acting screw-in cylinders with spring return are characterized by their compact design and are therefore often used as clamping cylinders. They can be positioned very close to each other. Due to the internal stroke limitation, these screw-in cylinders can be operated without an opposing clamping face. The double wipers installed as standard prevent dynamic leakage and thus increase the service life of the screw-in cylinders. The piston is reset to the initial position by means of an integrated spring.

Material

Housing and piston steel.

Seal NBR

Seal NBR

Version

Housing black oxidized.

Piston hardened.

Piston hardened.

Note

The screw-in cylinders can withstand maximum loads in both the tensioned and untensioned state.

To avoid damage to the seals during installation, make sure that the lead-in chamfers as well as the transverse holes for the oil supply are well rounded.

A sealing ring at the bottom of the screw-in hole seals the screw-in cylinder.

Due to the plunger design, no venting of the rod space is required.

The screw-in cylinders should be protected from aggressive cutting and cooling agents.

Thrust pieces for style B are not supplied.

Follow safety instructions.

To avoid damage to the seals during installation, make sure that the lead-in chamfers as well as the transverse holes for the oil supply are well rounded.

A sealing ring at the bottom of the screw-in hole seals the screw-in cylinder.

Due to the plunger design, no venting of the rod space is required.

The screw-in cylinders should be protected from aggressive cutting and cooling agents.

Thrust pieces for style B are not supplied.

Follow safety instructions.

Method of operation

Drilled channels.

Technical Data

Max. operating pressure: 400 bar.

Assembly

See mounting contour.

Advantages

- Integrated metal wiper.

- Low mounting dimensions.

- Can be used without opposing clamping face.

- Loads in retracted position possible.

- Lineless pressure supply.

- Low mounting dimensions.

- Can be used without opposing clamping face.

- Loads in retracted position possible.

- Lineless pressure supply.

Drawing reference

1) Mounting contour

Accessory

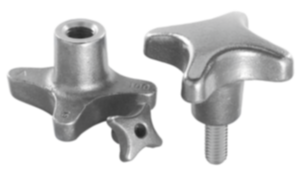

Style B:

- Rest pads K0307.

- Self-aligning pads K0282, K0302, K1164, K0287, K0288.

- Gripper screws, hexagonal K0386.

- Rest pads K0307.

- Self-aligning pads K0282, K0302, K1164, K0287, K0288.

- Gripper screws, hexagonal K0386.